Top Discharge Centrifuge

The Manual Top Discharge centrifuge is the basic model of the centrifuge where the filtered cake is manually scooped out by the operator. This centrifuge is the most commonly used type and is also the most economical.

Sizes Available: Starting from 12” Dia. up to 60” Diameter.

Materials of Construction: SS 316, SS 304, SS904L, Hastelloy & Titanium

Coating: Halar (ECTFE), Teflon (PFA), Rubber Lining, FRP Lining

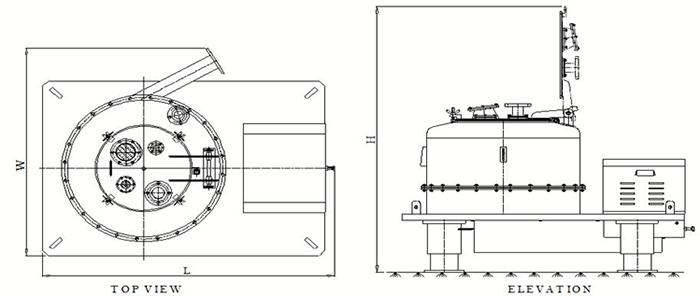

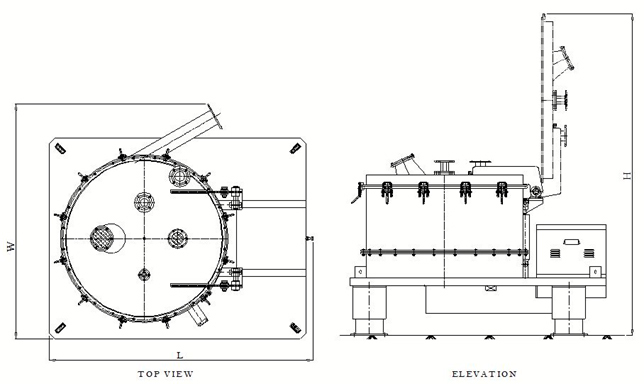

1. Partial Lid Opening: In this model the lid of the centrifuge only a portion of the top cover of the centrifuge is opened to scoop out the cake. For complete cleaning of the basket and inner parts of the centrifuge the monitor casing of the centrifuge has to be opened.

2. Full Lid Open: In this variant the top lid of the centrifuge has a large diameter that equals the diameter of the monitor casing. This gives better access to basket inside and outer periphery (except bottom) and full access to the top cover.

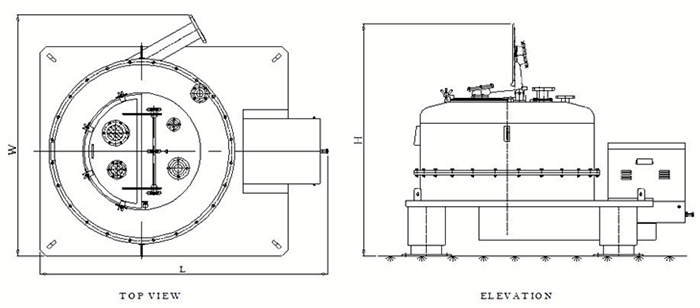

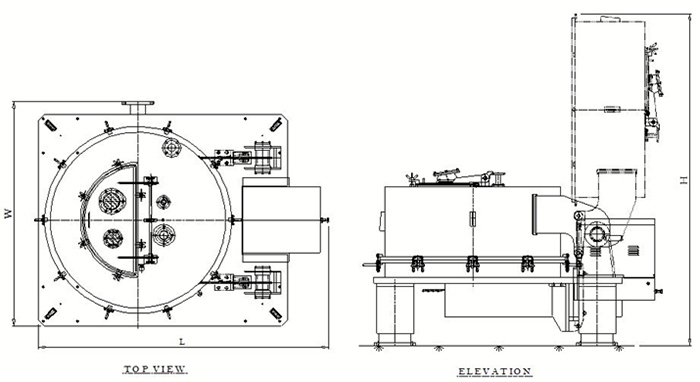

3. Full Body Opening: In this model the entire top cover of the centrifuge is accessible for cleaning and visual inspection. This is an ideal model for applications involving product changeovers and special cleaning needs. The basket bottom and the Mother Liquor Drain platform can be visually seen in this model. This model is often called cGMP or sanitary model.

4. Full Lid Opening and Full Body opening: In this model both the lid and the Monitor Casing can be opened out for cleaning. In case it is only required to unload the product the top lid can be opened and the cake can be discharged. In case it is necessary to inspect the basket or other parts of the centrifuge the entire monitor casing can be opened.

The Lid opening options are: Spring Operated Pneumatically operated or Hydraulically operated systems.

Optional Extras: Nitrogen Blanketing, Vibration Limiter, RPM Sensor with Indicator, Zero Speed Interlock, Cleaning in Place (CIP), Cake thickness sensor, Pneumatic Lid Opening System, Hydraulic Lid or Body opening systems

Technical Data Sheet

| VBC-TD | 24" x 12 " | 32" x 16 " | 36" x 18" | 48" x 20" | Unit |

|---|---|---|---|---|---|

| Basket diameter | 610 | 800 | 915 | 1210 | [mm] |

| Basket height | 300 | 410 | 460 | 490 | [mm] |

| Filter surface Area | 0.57 | 1 | 1.32 | 1.86 | [m2] |

| Useful volume | 45 | 100 | 159 | 300 | [dm3] |

| Max. load | 45 | 100 | 159 | 300 | [kg] |

| Max. load @ Bulk Density 1.0 | 1200 | 1100 | 1100 | 900 | rpm |

| Max. G force | 485 | 541 | 620 | 550 | |

| Centrifuge weight (with load) | 700 | 2000 | 2200 | 3200 | [kg] |

| Motor power for main drive | 3 | 7.5 | 7.5 | 15 | [HP] |

| Dimensions | |||||

| L | 1450 | 1900 | 2000 | 2250 | [mm] |

| W | 1100 | 1550 | 1600 | 2000 | [mm] |

| H (Lid Open Condition) | 1550 | 2000 | 2100 | 2250 | [mm] |

| VBC-TD | 48" x 20" | 48" x 24" | 60" x 20" | 60" x 24" | Unit |

|---|---|---|---|---|---|

| Basket diameter | 1210 | 1210 | 1500 | 1500 | [mm] |

| Basket height | 500 | 610 | 510 | 610 | [mm] |

| Filter surface Area | 1.9 | 2.3 | 2.4 | 2.87 | [m2] |

| Useful volume | 300 | 350 | 500 | 600 | [dm3] |

| Max. load @ Bulk Density 1.0 | 300 | 350 | 500 | 600 | [kg] |

| Max. speed of Basket | 900 | 900 | 800 | 800 | rpm |

| Max. G force | 550 | 550 | 540 | 540 | |

| Centrifuge weight (with load) | 3200 | 3300 | 5200 | 5400 | [kg] |

| Motor power for main drive | 15 | 15 | 20 | 20 | [HP] |

| Dimensions | |||||

| L | 2250 | 2250 | 2700 | 2700 | [mm] |

| W | 2000 | 2000 | 2300 | 2300 | [mm] |

| H (Lid Open Condition) | 1900 | 2000 | 2150 | 2250 | [mm] |

| VBC-TD FLO | 36" x 18" | 36" x 20" | 48" x 20" | 48" x 24" | 60" x 20" | 60" x 24" | Unit |

|---|---|---|---|---|---|---|---|

| Basket diameter | 915 | 915 | 1210 | 1210 | 1500 | 1500 | [mm] |

| Basket height | 460 | 500 | 500 | 610 | 510 | 610 | [mm] |

| Filter surface Area | 1.32 | 1.32 | 1.9 | 2.3 | 2.4 | 2.87 | [m2] |

| Useful volume | 159 | 172 | 300 | 350 | 500 | 600 | [dm3] |

| Max. load | 159 | 172 | 300 | 350 | 500 | 600 | [kg] |

| Max. speed of Basket | 1100 | 1100 | 900 | 900 | 800 | 800 | rpm |

| Max. G force | 620 | 620 | 550 | 550 | 540 | 540 | |

| Centrifuge weight (with load) | 2200 | 2250 | 3400 | 3500 | 5300 | 5500 | [kg] |

| Motor power for main drive | 7.5 | 7.5 | 15 | 15 | 20 | 20 | [HP] |

| Dimensions | |||||||

| L | 2050 | 2050 | 2250 | 2250 | 2750 | 2750 | [mm] |

| W | 1650 | 1650 | 2000 | 2000 | 2300 | 2300 | [mm] |

| H (Lid Open Condition) | 2500 | 2550 | 2850 | 2850 | 3400 | 3500 | [mm] |

| VBC-TD FBO | 36" x 18" | 36" x 20" | 48" x 20" | 48" x 24" | 60" x 20" | 60" x 24" | Unit |

|---|---|---|---|---|---|---|---|

| Basket diameter | 915 | 915 | 1210 | 1210 | 1500 | 1500 | [mm] |

| Basket height | 460 | 500 | 500 | 610 | 510 | 610 | [mm] |

| Filter surface Area | 1.32 | 1.43 | 1.9 | 2.31 | 2.4 | 2.87 | [m2] |

| Useful volume | 159 | 172 | 300 | 350 | 500 | 600 | [dm3] |

| Max. load | 159 | 172 | 300 | 350 | 500 | 600 | [kg] |

| Max. speed of Basket | 1100 | 1100 | 900 | 900 | 800 | 800 | rpm |

| Max. G force | 620 | 620 | 550 | 550 | 540 | 540 | |

| Centrifuge weight (with load) | 2800 | 3000 | 3500 | 3600 | 6000 | 6200 | [kg] |

| Motor power for main drive | 7.5 | 7.5 | 15 | 15 | 25 | 25 | [HP] |

| Dimensions | |||||||

| L | 2200 | 2200 | 2350 | 2350 | 2800 | 2800 | [mm] |

| W | 1450 | 1450 | 1800 | 1800 | 2350 | 2350 | [mm] |

| H (Body Open Condition) | 2150 | 2200 | 2700 | 2800 | 2800 | 2900 | [mm] |

- 4 Point Suspension: Centrifuge is mounted on four viscous Dampers.

- Variable Frequency Drive: The operating speeds of the centrifuge are controlled by a Variable Frequency Drive. The Standard Braking System for this model is Dynamic Braking.

- Taper Lock Pulleys: These pulleys are easier to mount and dismount.

- Cake Washing Nozzles: Special Spray nozzles with defined conical pattern spray are provided so that the entire surface of the cake is covered uniformly with minimal quantity while maintaining repeatable washing performance.

- Shaft Protection Sleeve: A stainless Steel sleeve is mounted on the exposed part of the shaft to protect it from corrosion.

- Proximity Sensor: To prevent the machine from being started while the lid is open a proximity sensor is installed as a standard feature.

- Gas Tight Design: The machine is constructed to retain a positive pressure of 400mm WC as per DIN 24400.

- Easy Maintenance: The machine design affords minimal maintenance. Greasing points enable easy lubrication to the Bearings.