Pharma Peeler Centrifuges

In this machine process system is separated from service system. All maintenance activities will be carried out in service area which can locate outside the clean room by installing the machine through the wall.

The horizontal peeler centrifuge is known for its many advantages from its horizontal rotation arrangement of the basket. By arranging the axis horizontally, advantages in washing capability, uniform solid size distribution for better solid output quality. The feeding action in centrifuge is effective as the feeds are fed perpendicularly to gravity and centrifugal force spreads out the solids evenly on basket inner surface.

Also the casing of the centrifuge can be fully opened which allows easy access to inside of rotating basket. This also means the operator can get access to internal components including filter cloth which required replacement.

And its high discharge speed reduces time taken to accelerate and braking for rotation for high capacity, so does power consumption, wear and tear. This short cycle time is particularly beneficial for short cycle, fast-filtering requirements for certain processes. This means these centrifuges provide higher centrifugal forces than vertical centrifuges, and increases performances and flexibility.

Due to continuous discharge of filtered liquid through perforated inner surface of rotating basket, the pressure drop, main driving force of filtration is increased across the solid cake and filter medium; as a result, the filtration rate can be boosted.

Moreover, high rotational speed results high rotational force which allows lowering residual cake moisture effectively, so does the washing liquid and washing results. Because of effective washing, drying processes that yield high purity of output.

In this model the cake is filtered in the same manner as the vertical models but the cake discharge is achieved by means of a scraper knife that plows into the cake. At this point the basket is in rotation at a preset low speed and the cake is peeled off the Basket surface and discharged through the discharge chute which was mounted on outer casing.

The filter bags in these centrifuges are held in place by Tensioned Rings or by screws and the bags may also have backing cloth or mesh to impart structural rigidity to the bag so that the bag does not distort of collapse while the knife is being engaged.

The small gap between the scraper and the Basket Shell results in a thin layer of cake remaining inside the Basket. This layer is known as the Residual Heel. A Blow Off arrangement is provided to remove this Heel. Typically this is achieved by a blast of Air/ Nitrogen from specially arranged Air Delivery nozzles mounted on a pipe. The pipe is aligned with the basket perforations so that when the blast of Air is sent in to the pipe it travels through the Basket perforations and dislodges the Residual Heel.

The action of the scraper knife is by means of a Hydraulic Cylinder which is powered by a Hydraulic Power Pack.

The Scraper knife has mechanical limits so that the knife does not accidentally come in contact with the Basket Shell.

Sizes Available: Starting from 24” Dia. up to 60” Diameter.

Materials of Construction: SS 316, SS 304, SS904L, Hastelloy & Titanium

Coating: Halar (ECTFE), Teflon (PFA)

Technical data sheet

| HPC-Phar. | 24" x 12" | 32" x 16" | 32" x 20" | 40" x 20" | 50" x 25" | 50" x 32" | 60" x 32" | Unit |

|---|---|---|---|---|---|---|---|---|

| Basket diameter | 630 | 800 | 800 | 1000 | 1250 | 1250 | 1500 | [mm] |

| Basket height | 320 | 400 | 500 | 500 | 630 | 800 | 800 | [mm] |

| Filter surface Area | 0.63 | 1.01 | 1.25 | 1.57 | 2.47 | 3.14 | 3.77 | [m2] |

| Useful volume | 41 | 80 | 100 | 170 | 326 | 415 | 640 | [dm3] |

| Max. load @ Bulk Density 1.0 | 41 | 80 | 100 | 170 | 326 | 415 | 640 | [kg] |

| Max. speed of Basket | 2400 | 1800 | 1800 | 1500 | 1200 | 1200 | 950 | rpm |

| Max. G force | 2028 | 1449 | 1449 | 1258 | 1006 | 1006 | 757 | |

| Centrifuge weight (with load) | 4000 | 5750 | 6000 | 9500 | 13500 | 14000 | 19000 | [kg] |

| Motor power for main drive | 10 | 20 | 20 | 30 | 50 | 50 | 75 | [HP] |

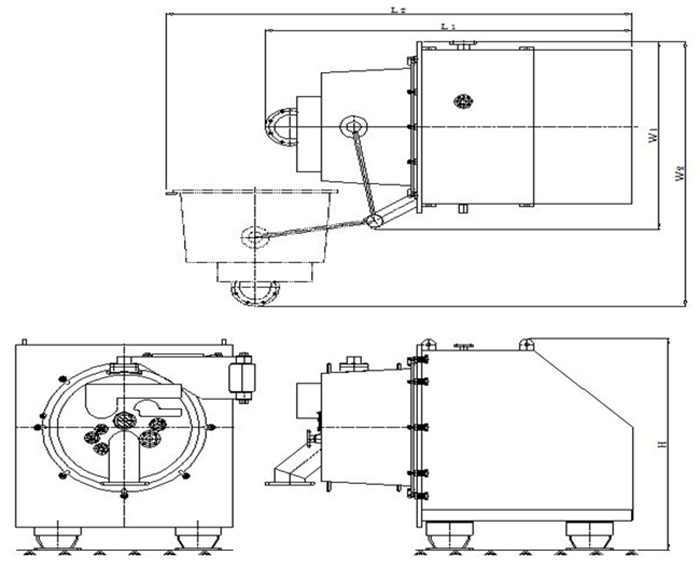

| Dimensions | ||||||||

| L1 (Lid Closed ) | 2250 | 2450 | 2550 | 2850 | 3250 | 3500 | 4000 | [mm] |

| L2 (Lid Opened) | 3000 | 3100 | 3200 | 3600 | 4100 | 4400 | 5000 | [mm] |

| W1 (Lid Closed) | 1550 | 1700 | 1700 | 2000 | 2400 | 2400 | 2850 | [mm] |

| W2 (Lid Opened) | 2050 | 2400 | 2400 | 2800 | 3250 | 3250 | 4000 | [mm] |

| H | 1700 | 1950 | 1950 | 2350 | 2400 | 2400 | 2800 | [mm] |

- 4 Point Suspension: Centrifuge is mounted on four viscous Dampers.

- Variable Frequency Drive: The operating speeds of the centrifuge are controlled by a Variable Frequency Drive. The Standard Braking System for this model is Dynamic Braking.

- Taper Lock Pulleys: These pulleys are easier to mount and dismount.

- Cake Washing Nozzles: Special Spray nozzles with defined conical pattern spray are provided so that the entire surface of the cake is covered uniformly with minimal quantity while maintaining repeatable washing performance.

- Shaft Protection Sleeve: A stainless Steel sleeve is mounted on the exposed part of the shaft to protect it from corrosion.

- Proximity Sensor: To prevent the machine from being started while the lid is open a proximity sensor is installed as a standard feature.

- Gas Tight Design: The machine is constructed to retain a positive pressure of 400mm WC as per DIN 24400.

- Easy Maintenance: The machine design affords minimal maintenance. Greasing points enable easy lubrication to the Bearings.