Signature Products

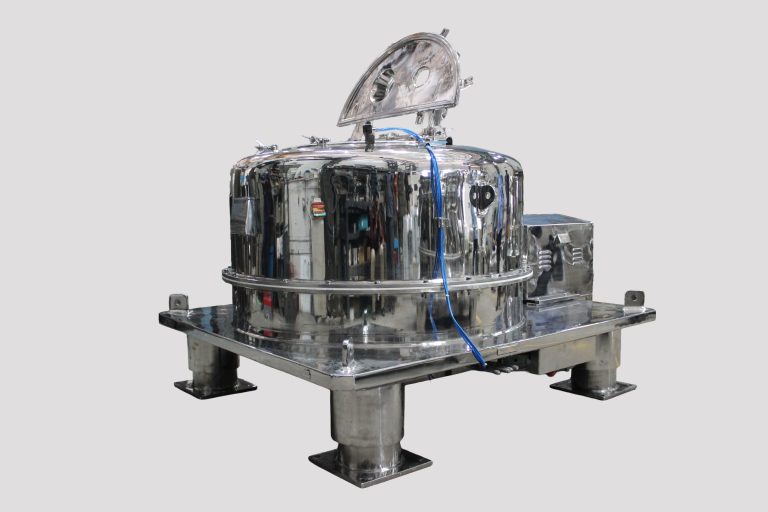

Bottom Discharge / Vertical Scraper Centrifuge

A fully automatic scraper centrifuge for continuous operation. Feeding, separation, washing, and discharging are all automated, enabling hands-free processing. Widely used in the Pharma and Fine Chemicals industries, it maximizes throughput and minimizes labor. Key advantages include high capacity, consistent cake dryness, easy integration in process lines and high quality, contamination free cake.

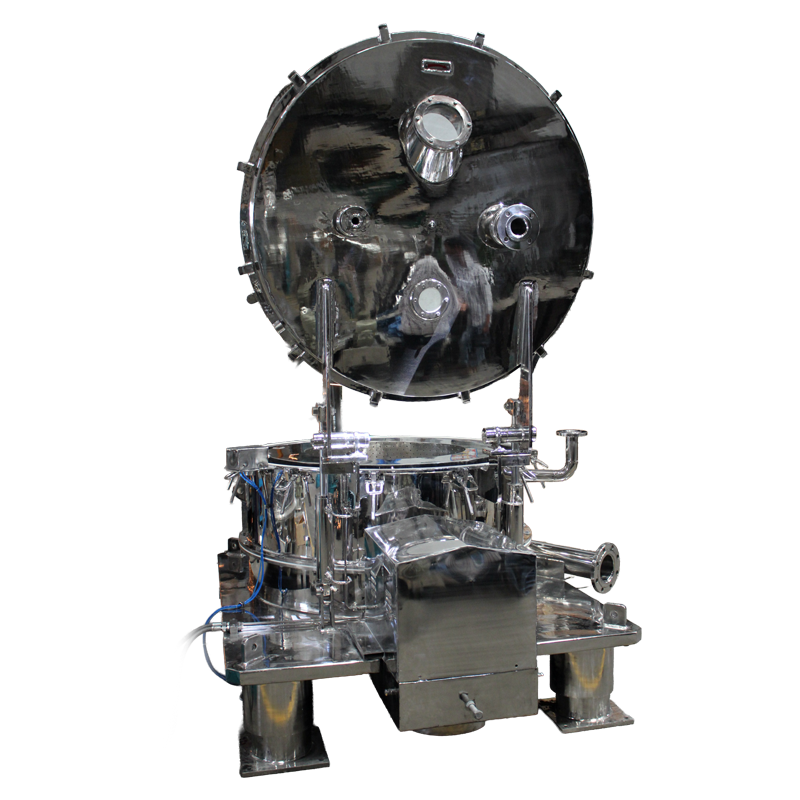

Horizontal Pharma Peeler Centrifuge

A fully automatic scraper centrifuge for continuous operation. Feeding, separation, washing, and discharging are all automated, enabling hands-free processing. Widely used in the Pharma and Fine Chemicals industries, it maximizes throughput and minimizes labor. Key advantages include high capacity, consistent cake dryness, easy integration in process lines and high quality, contamination free cake.

All Products

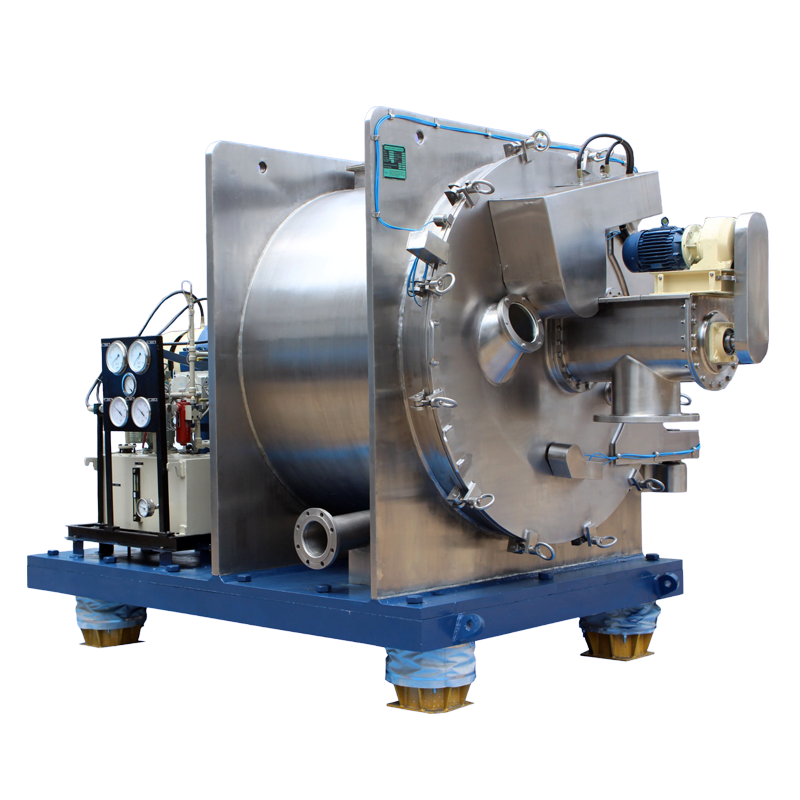

Bottom Discharge (Vertical Scraper) Centrifuge

The Bottom Discharge Centrifuge, also widely known as the Vertical Peeler Centrifuge in Europe, is a fully automatic solid-liquid separation system designed for efficient handling of medium to large batch processes.

Bag Lifting Centrifuge

The Bag Lifting Centrifuge is an advanced version of the Manual Top Discharge Centrifuge, designed for higher productivity, easier handling, and improved operator safety. This centrifuge is the ideal choice for medium- and large-scale production plants

Manual Top Discharge Centrifuge

The Manual Top Discharge Centrifuge is one of the most traditional and widely used solid–liquid separation machines in the process industry. Known for its simple design, rugged construction, and proven reliability,

Laboratory and Pilot Centrifuge

The Laboratory and Pilot Plant Centrifuges are specially designed for research, process development, and small-scale production trials. Compact yet versatile, these machines have become an essential tool before

Chemical Peeler Centrifuge

The Horizontal Chemical Peeler Centrifuges are robust and high-capacity machines designed for demanding chemical process industries. These centrifuges handle a wide range of products including corrosive, abrasive,

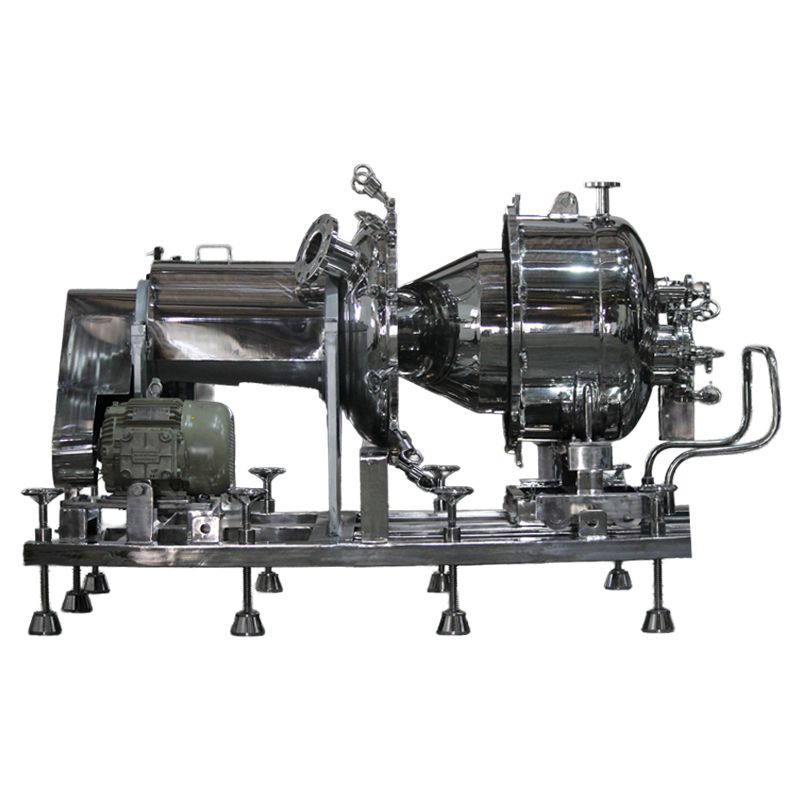

Pharma Peeler Centrifuge

Pharma Peeler Centrifuges are specially designed for critical applications in the pharmaceutical and fine chemical industries where hygiene, product purity, and ease of cleaning are paramount. These machines are built with a clear separation

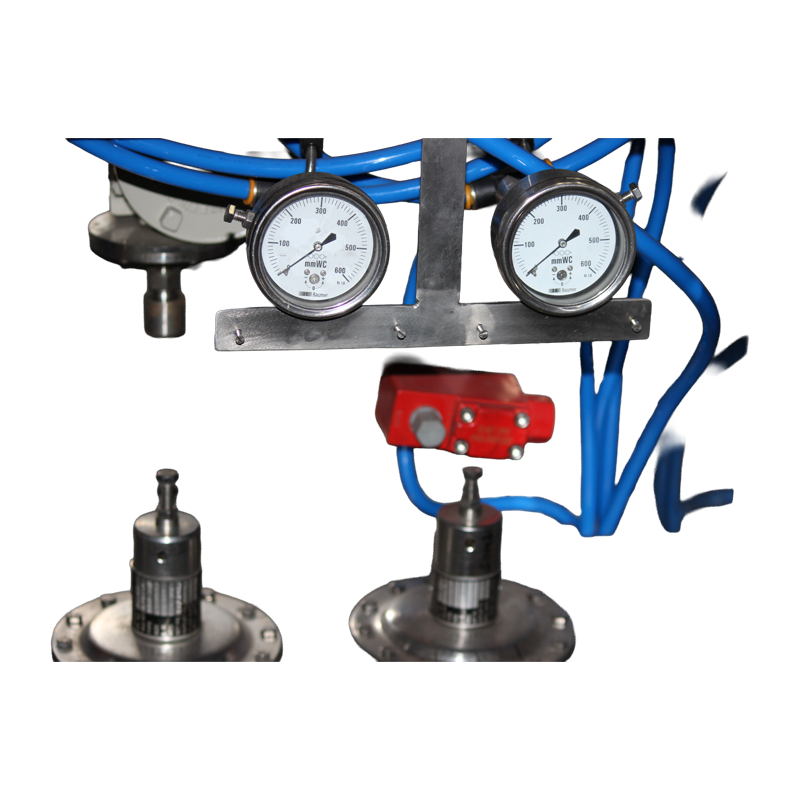

Inertization System

Handling volatile or flammable solvents inside a centrifuge requires the highest degree of safety and reliability. To meet these critical requirements, our centrifuges can be equipped with a Nitrogen Blanketing (Inertization) System, which creates a safe, oxygen-controlled environment inside the machine.

ANFD

The Agitated Nutsche Filter Dryer (ANFD) is a versatile, closed-system equipment used for solid–liquid separation, cake washing, and drying in a single, compact unit. Designed for handling toxic, hazardous, or solvent-laden products, the ANFD ensures safe,

Centrifugal Thin Film Evaporator (Centrithor)

The Centrithor is a next-generation centrifugal thin film evaporator designed for efficient evaporation, concentration, and purification of heat-sensitive, viscous, and high-value products. Unlike conventional evaporators, the Centrithor uses centrifugal force to spread

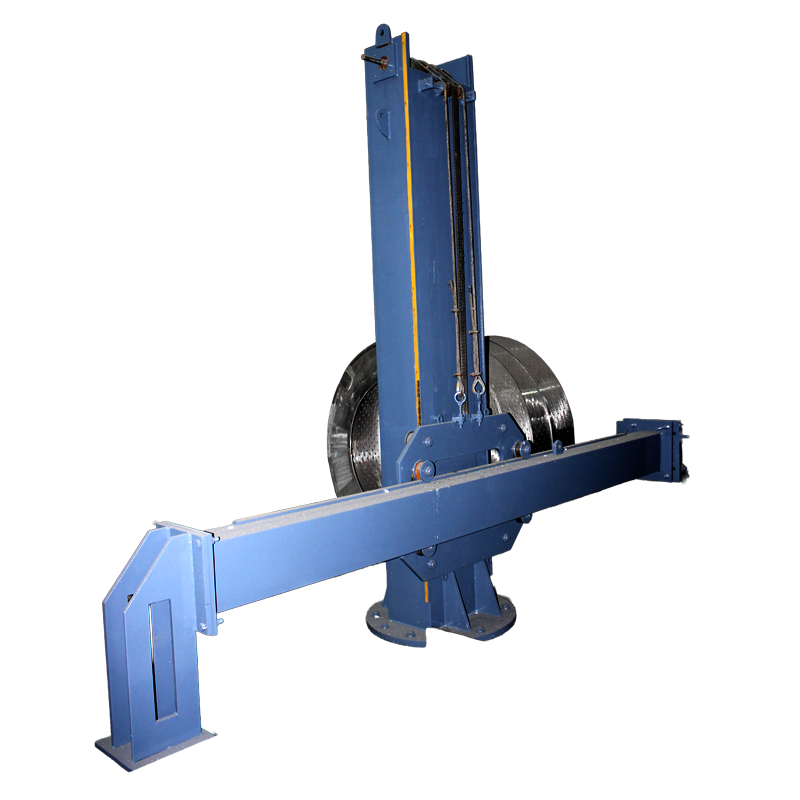

Automated Buffing Machine

The Automated Polishing Machine with column and boom construction is designed for efficient surface finishing of large process equipment such as centrifuges, pressure vessels, reactors, and storage tanks. By combining automation with precise mechanical control

Design Variants

Half Lid Open

The Half Lid Open or Partial Lid Open centrifuge consists of the top Lid with only a portion of the body, which is opened to manually scoop the cake from the basket. For servicing, cleaning and troubleshooting, the entire Monitor casing needs to be opened, increasing servicing and maintenance time, ideal for small scale operations

Full Lid Open

In this model, the Lid is a large rounded dished (or) square shell type support whose diameter matches the diameter of the Monitor casing and can be fully opened to get better access to the basket and inner shell regions, except for the bottom plate, hence cleaning is ideally less time consuming compared to the Half Lid Open model

Round Lid Open

Similar to Half Lid Open, with more area for personnel access during manual scooping of cake

Full Body Open

For special cleaning and maintenance needs, the Full Body Open type model allows for clear visual inspection and cleaning of the basket, monitor casing and bottom liquid discharge plate for repeated product changeovers and strict quality control.

General Machine Features

Safety Features

Additional Features

Clean-In-Place (CIP) System

Our centrifuges can be equipped with Clean-In-Place (CIP) systems to ensure thorough cleaning of all product-contact surfaces without dismantling the machine. Strategically placed spray nozzles and rotary spray balls deliver high-pressure cleaning fluids inside the basket, casing, and discharge zones.

Key Features

- Automatic cleaning cycles integrated with PLC

- Uniform coverage with optimized spray nozzles

- Safe drainage of wash liquids

Advantages

- Ensures GMP compliance and validated cleaning

- Minimizes downtime between batches

- Eliminates manual cleaning, improving operator safety

- Prevents cross-contamination during product changeover

Bag Lifting Device

The Bag Lifting Device is an optional hydraulic hoist provided with Bag Lifting Centrifuges to simplify cake discharge and handling. After the filtration cycle, the hydraulic lifting arrangement raises the filter bag with the cake load directly out of the basket. The device allows 360° free rotation, enabling the operator to conveniently position and discharge the cake at the desired location.

This arrangement eliminates manual scraping, reduces operator exposure to process material, and ensures quick turnaround between batches. The design is compact, reliable, and particularly suitable for handling bulk, sticky, or hazardous cakes where manual discharge would be difficult or unsafe.

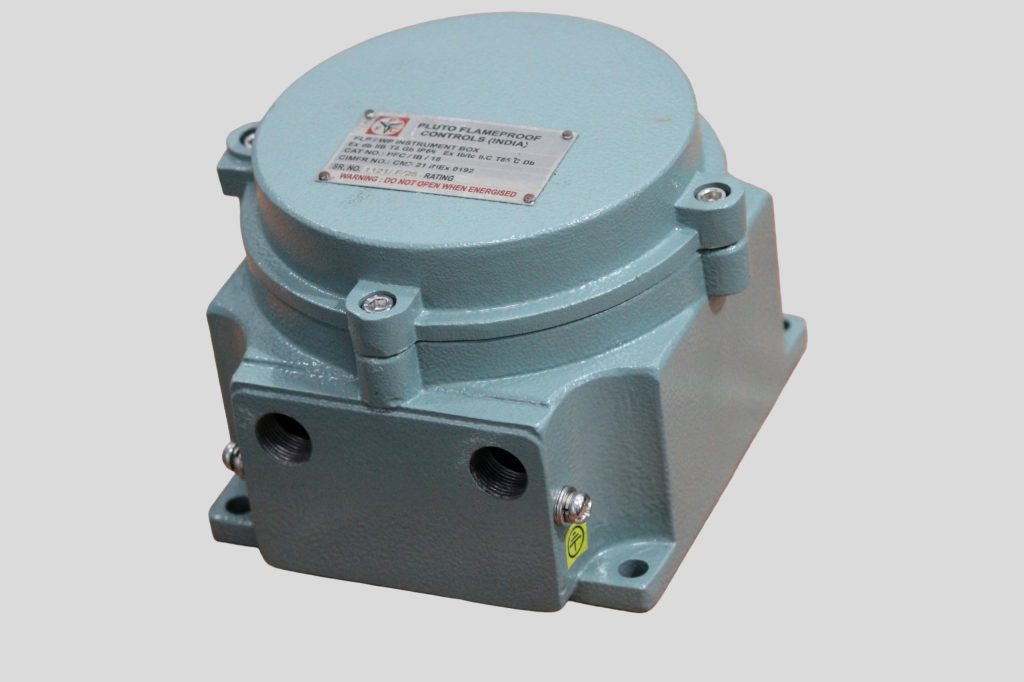

Human Machine Interface (PLC Based systems)

A Dedicated Human Machine Interface system is integrated with Joflo machines, which make operation especially flexible, but mostly preferred in Hazardous areas of Application, where risk to human life due to process is imminent. These systems are available in both the traditional Key Pad systems and most modern Touch screen control surfaces. With upgradation from the electronics and implementation of Artificial Intelligence, Joflo shows commitment towards advanced cost-effective machining applications.

Traditional PLC Controllers sourced from Mitsubishi and ABB, are some of the best machine control equipment that have dominated the market since the last few decades, the PLC Controllers are used for semi and fully automatic applications for some of our most complex machines such as the Bottom Discharge centrifuges and the Horizontal Peeler Centrifuges.

Harnessing advanced automation, our systems utilize PLCs to precisely control all machine functions from start-up to cycle completion.