Laboratory centrifuges

Over the years we have studied the procedures followed in R&D labs and have found that a convenient centrifugation method was not available.

To fill this gap we developed a small centrifuge that is portable and easy to operate. The batch sizes range from 5 to 10 liters.

These models are ideal for Kilo Lab applications besides regular R&D Labs. They are manufactured to be deployed in GMP environments.

Not only Kilo Lab applications, Pilot plant operations are also becoming more important as several high value products are manufactured in a small scale. These models have batch volumes ranging between 28 Liters to 45 Liters and are available in fixed and portable formats.

As these products must be produced in a similar GMP environment and should use equipment similar to those that would be used when the volume of production increases and when the production is moved into a commercial scale plant.

These Centrifuges usually manual top discharge machines and are used for small batches in plant and R&D laboratory experiments.

These machines are not required heavy foundations can be placed on trolleys to move easily to specified operational zones.

These machines can be supplied with or without trolley depends on customers requirement.

Sizes Available: Starting from 12” Dia. up to 24” Diameter.

Materials of Construction: SS 316, SS 304, SS904L, Hastelloy & Titanium

Coating: Halar (ECTFE), Teflon (PFA)

Technical data sheet

| VBC-TD FLO | 12" x 8" | 14" x 7" | 18" x 10" | 24" x 12" | Unit |

|---|---|---|---|---|---|

| Basket diameter | 300 | 360 | 457 | 610 | [mm] |

| Basket height | 200 | 175 | 250 | 300 | [mm] |

| Filter surface Area | 0.18 | 0.2 | 0.36 | 0.57 | [m2] |

| Useful volume | 9 | 13 | 29 | 46 | [dm3] |

| Max. load @ Bulk Density 1.0 | 9 | 13 | 29 | 46 | [kg] |

| Max. speed of Basket | 3000 | 3000 | 2000 | 1400 | rpm |

| Max. G force | 1534 | 1830 | 1025 | 671 | |

| Centrifuge weight (with load) | 300 | 350 | 500 | 700 | [kg] |

| Motor power for main drive | 1.5 | 2 | 2 | 3 | [HP] |

| Dimensions | |||||

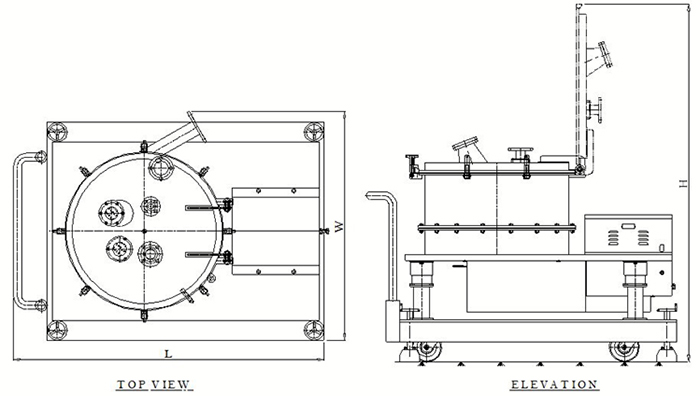

| L | 1300 | 1300 | 1300 | 1550 | [mm] |

| W | 850 | 850 | 900 | 1100 | [mm] |

| H (Lid Open Condition) | 1200 | 1250 | 1600 | 1850 | [mm] |

| VBC-TD FBO | 12" x 8" | 14" x 7" | 18" x 10" | 24" x 12" | Unit |

|---|---|---|---|---|---|

| Basket diameter | 300 | 360 | 457 | 610 | [mm] |

| Basket height | 200 | 175 | 250 | 300 | [mm] |

| Filter surface Area | 0.18 | 0.2 | 0.36 | 0.57 | [m2] |

| Useful volume | 9 | 13 | 29 | 46 | [dm3] |

| Max. load @ Bulk Density 1.0 | 9 | 13 | 29 | 46 | [kg] |

| Max. speed of Basket | 3000 | 3000 | 2000 | 1400 | rpm |

| Max. G force | 1534 | 1830 | 1025 | 671 | |

| Centrifuge weight (with load) | 325 | 360 | 500 | 700 | [kg] |

| Motor power for main drive | 1.5 | 2 | 2 | 3 | [HP] |

| Dimensions | |||||

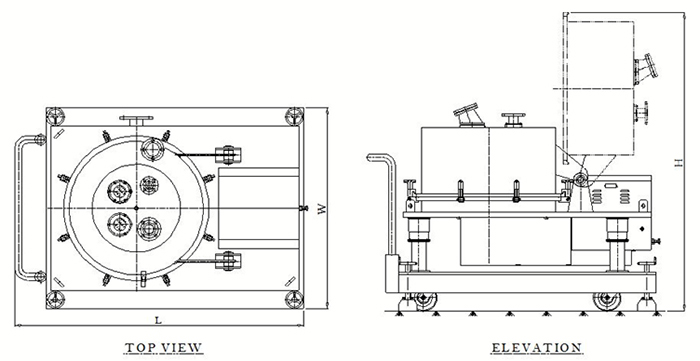

| L | 1250 | 1250 | 1400 | 1550 | [mm] |

| W | 850 | 850 | 850 | 1100 | [mm] |

| H (Body Open Condition) | 1150 | 1200 | 1400 | 1550 | [mm] |

- 4 Point Suspension: Centrifuge is mounted on four viscous Dampers.

- Variable Frequency Drive: The operating speeds of the centrifuge are controlled by a Variable Frequency Drive. The Standard Braking System for this model is Dynamic Braking.

- Taper Lock Pulleys: These pulleys are easier to mount and dismount.

- Cake Washing Nozzles: Special Spray nozzles with defined conical pattern spray are provided so that the entire surface of the cake is covered uniformly with minimal quantity while maintaining repeatable washing performance.

- Shaft Protection Sleeve: A stainless Steel sleeve is mounted on the exposed part of the shaft to protect it from corrosion.

- Proximity Sensor: To prevent the machine from being started while the lid is open a proximity sensor is installed as a standard feature.

- Gas Tight Design: The machine is constructed to retain a positive pressure of 400mm WC as per DIN 24400.

- Easy Maintenance: The machine design affords minimal maintenance. Greasing points enable easy lubrication to the Bearings.