Machining Powerhouse

"Grounded with conventional methods to ensure attention to detail and production efficiency"

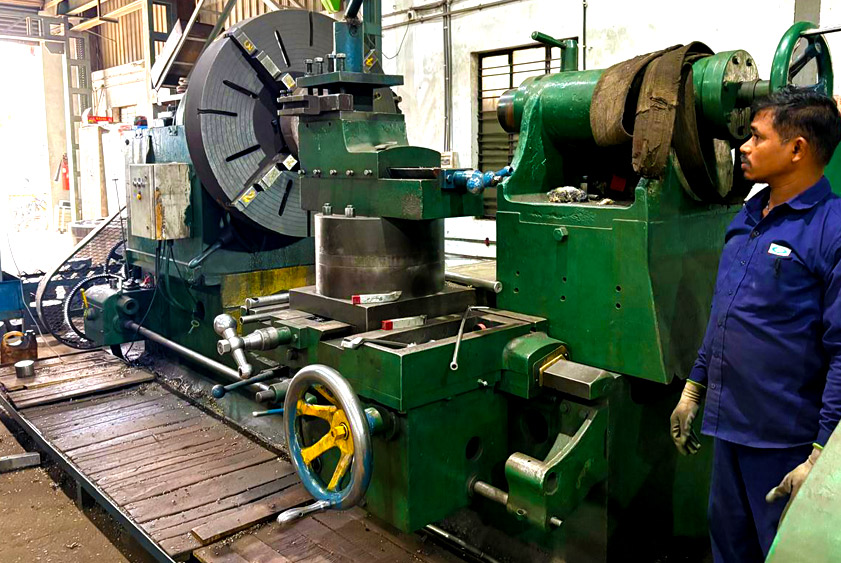

Conventional machining continues to be the powerhouse of manufacturing, forming the backbone of Joflo’s engineering excellence. With a diverse set of heavy-duty machines and decades of operator expertise, our facility ensures that every centrifuge is manufactured with precision, stability, and uncompromising reliability.

Our Hyderabad machining workshop spans over 4,500 sq. meters, equipped with both automated and conventional systems. The setup includes large-diameter lathes (up to 2 meters chuck size), precision lathes, milling machines, radial drilling machines, plate rolling machines, shaping machines, and rod cutting machines, supported by electric overhead cranes of 30-ton capacity for handling large assemblies. A 10-ton dynamic balancing machine, a distinctive feature of Joflo’s workshop, provides unmatched stability for centrifuge baskets operating at high rotational speeds.

- Balancing Machine ensures vibration-free, safe, and smooth performance of baskets under high-speed operation.

- Lathe Machines handle rough turning, shaping, and material removal for key components like baskets and monitor casings.

- Radial Drilling & Milling Machines enable versatile operations for structural and precision drilling & Milling requirements.

- Plate Rolling Machines support the forming of shells and casings with accuracy and consistency.

- Rod Cutting Machines streamline preparation of raw material for shafts and other critical components.

With this comprehensive capability, combined with 30 years of manufacturing expertise, Joflo has created a world-class machining and fabrication hub. Moving forward, we are strengthening this foundation further with our upcoming facility at the Atchutapuram Special Economic Zone, enabling expansion into the Heavy Engineering market while continuing to set new benchmarks in centrifuge manufacturing