Hyderabad Factory Premises

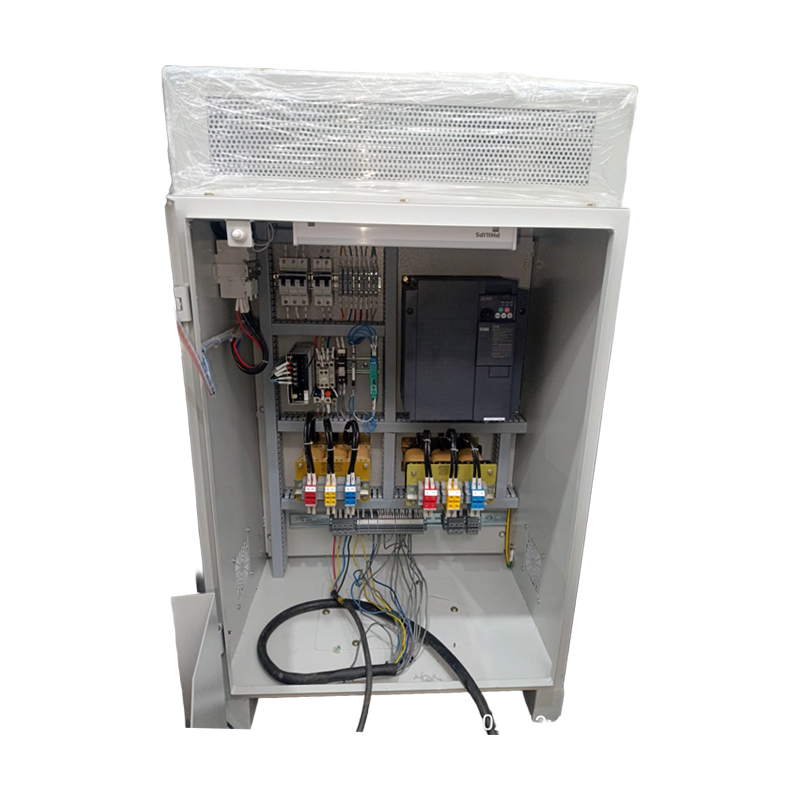

Starting from a piece of Land in 1993, to a 4500 square meter workshop area, with integrated state of the art office space for operational and management control and capable of production upwards of large machines per year, Joflo has successfully design, manufactured and deployed around 4000 machines to date, with varying degrees of complexity and operational flexibility. This facility is located in the Industrial Development Zone, IDA Mallapur, just opposite to Bharat Electronics Ltd (BEL) campus. The facility is home to 200 employees and an adopted dog, who’s in charge of our night time security!

Joflo Stores is a 200 square meter area that houses all of the equipment that is needed for precision manufacturing and production. They are responsible for on-time supply of all support equipment and never disappoint.

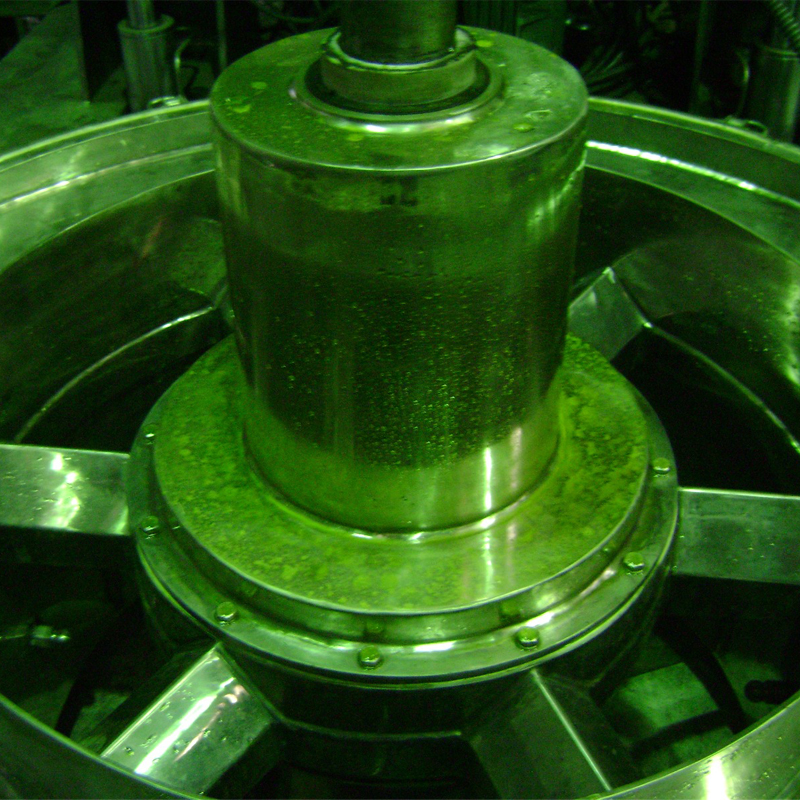

Through 25 years of relentless focus, our shop floors have evolved to produce upwards of 160 Machines per year. We give our clients a competitive edge towards cost effectiveness, machine quality and after sales servicing…

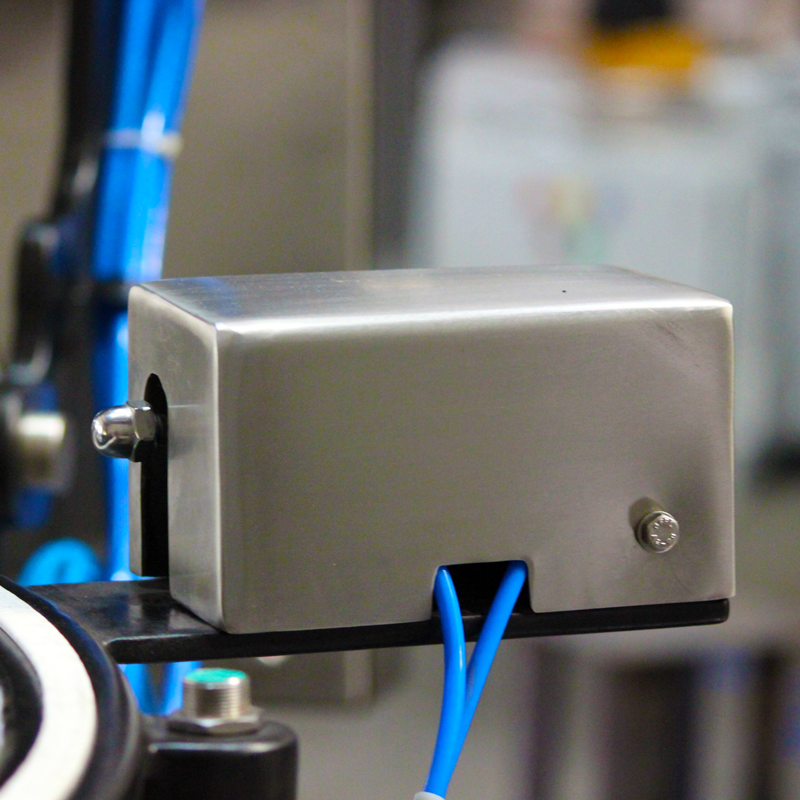

Materials and Equipment

Supporting Equipment

Surface Treatment and Coating

Joflo provides advanced surface treatment and coating solutions that protect process equipment from corrosion, abrasion, and chemical attack, ensuring long-term performance and reliability in the most demanding environments.

We offer a wide range of coatings including Graphite, Teflon (PTFE/PFA), Halar (ECTFE), polymer-based, rubber-based, and FRP linings, each carefully selected to match specific process requirements. For highly stressed areas, welded claddings are also provided to strengthen surfaces exposed to severe chemical or thermal conditions.

The strength of Joflo machines lies not only in robust engineering and precision design, but also in these specialized coatings, which enable equipment to withstand large temperature gradients, aggressive solvents, and high-speed filtration cycles without compromising safety or product quality.

All coatings are carried out through dedicated industry partners with decades of proven expertise in protective finishing, ensuring the highest standards of quality, consistency, and long-term reliability.

With these advanced treatments, Joflo ensures its equipment delivers consistent performance, superior safety, and long service life — even in the toughest process environments.

Joflo offers a wide range of coatings, which are summarized below:

Coating & Lifetime Enhancement

HALAR

ECTFE (Ethylene Chloro trifluoro ethylene)

RUBBER LINING

RUBBER LINING

GRAPHITE LINING

GRAPHITE LINING

TEFZEL

ETFE

(Ethylene Trifluoro ethylene)

FRP

Fiber Reinforced Plastic

PFA

Perfluoroalkoxy

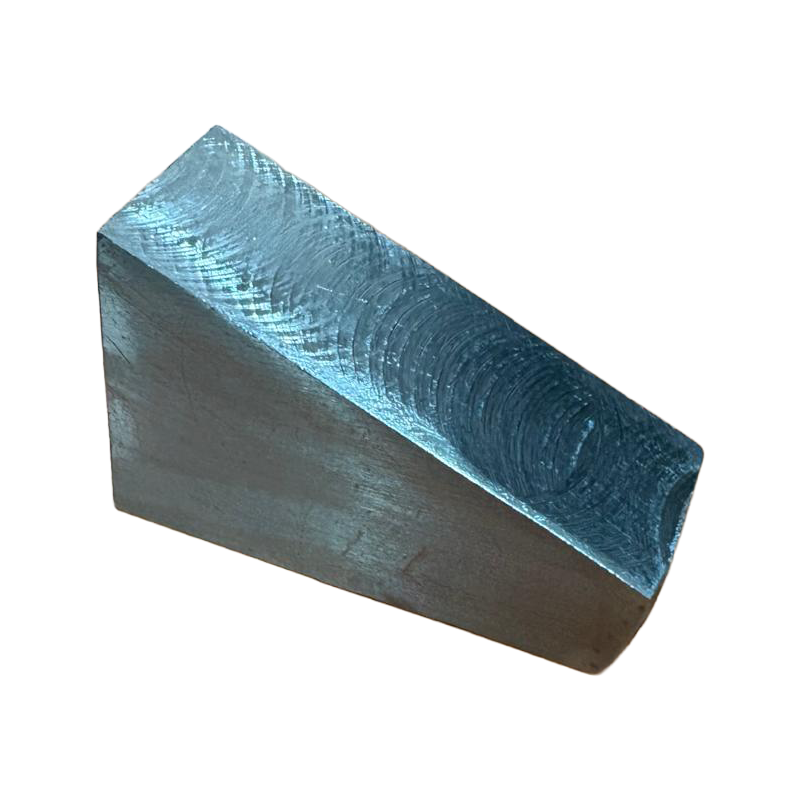

Cladding Solutions

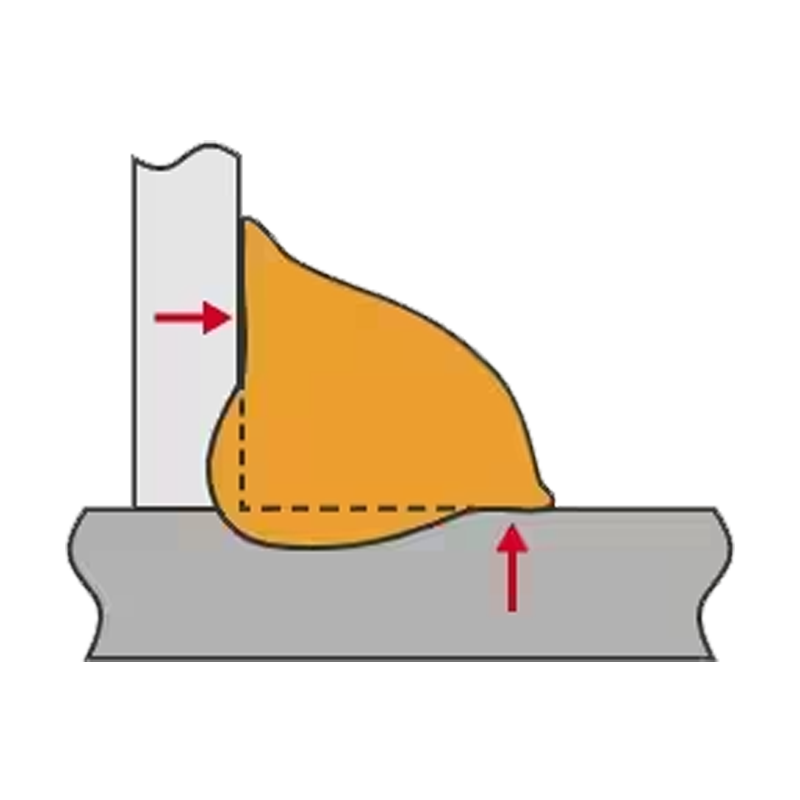

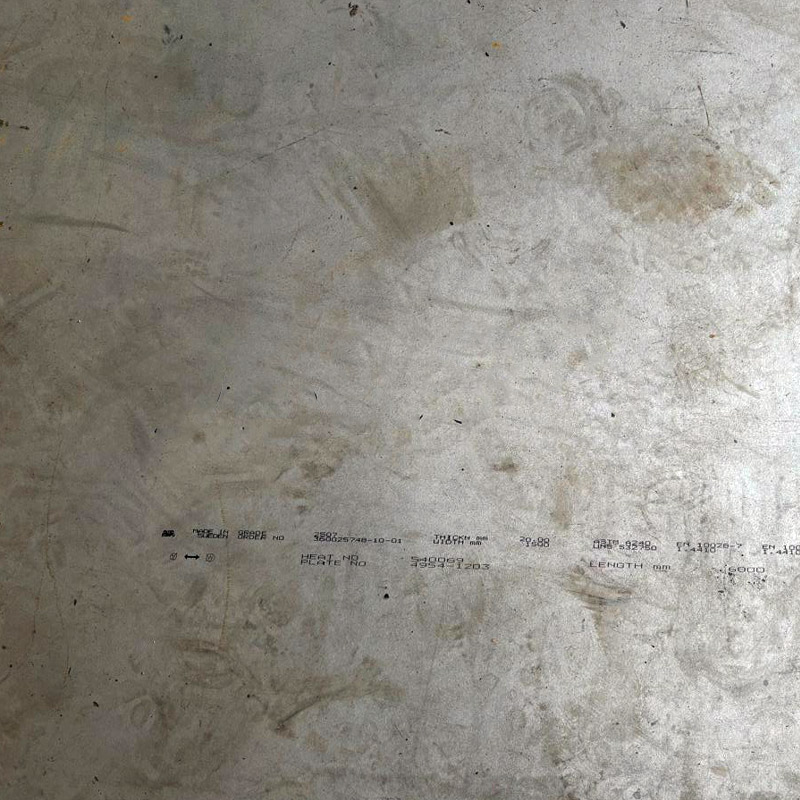

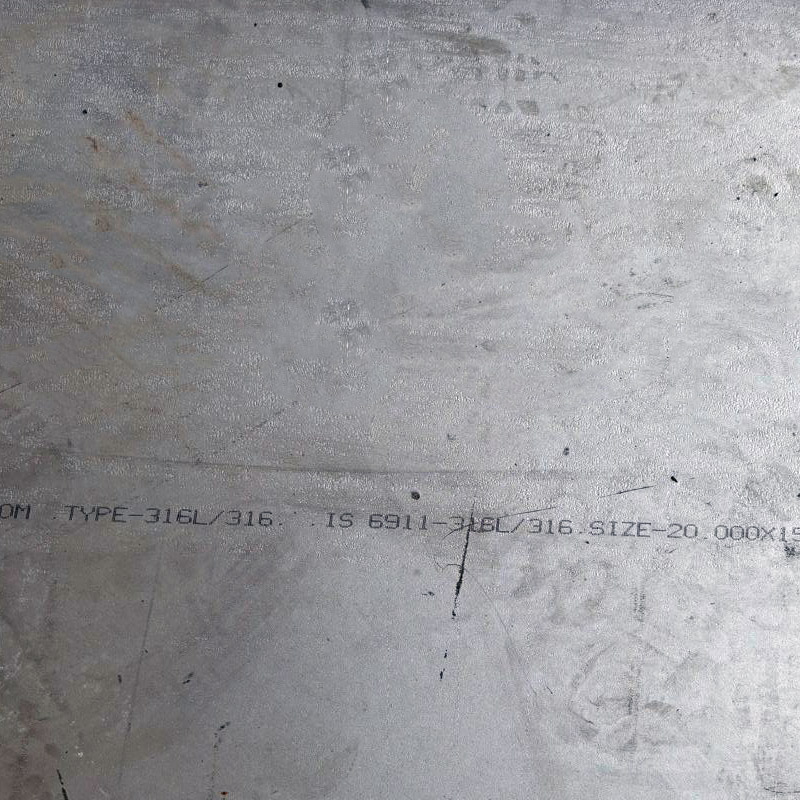

At Joflo, we provide specialized cladding solutions that enhance the durability of our centrifuges and process equipment while offering significant cost advantages. Instead of manufacturing the entire machine in a full-thickness exotic alloy such as Hastelloy (C-22 & C-276)or Alloy 20, explosion cladding technology allows us to bond a thin layer of corrosion-resistant alloy onto a robust base steel structure. This ensures the equipment achieves the same level of chemical resistance at a much lower cost.

Cladding is applied to critical wetted zones, discharge hoppers, and nozzles where direct contact with aggressive solvents and corrosive media occurs. For the basket shell and basket top, cladding is not applied, as these components contain perforations and are directly exposed to process material.

When required, Joflo can also supply centrifuges manufactured entirely from Hastelloy, Alloy 20, Inconel, or other exotic materials, ensuring flexibility to match the most demanding process conditions.

By combining explosion cladding with robust engineering design, Joflo delivers centrifuges that offer long service life, reduced equipment cost, superior resistance to corrosion, and safe operation — even in highly challenging environments.