Nitrogen Blanketing (Inertization) System

Handling volatile or flammable solvents inside a centrifuge requires the highest degree of safety and reliability. To meet these critical requirements, our centrifuges can be equipped with a Nitrogen Blanketing (Inertization) System, which creates a safe, oxygen-controlled environment inside the machine. By reducing oxygen concentration, the system eliminates the risk of ignition and explosion, while allowing the process to continue smoothly without compromising efficiency.

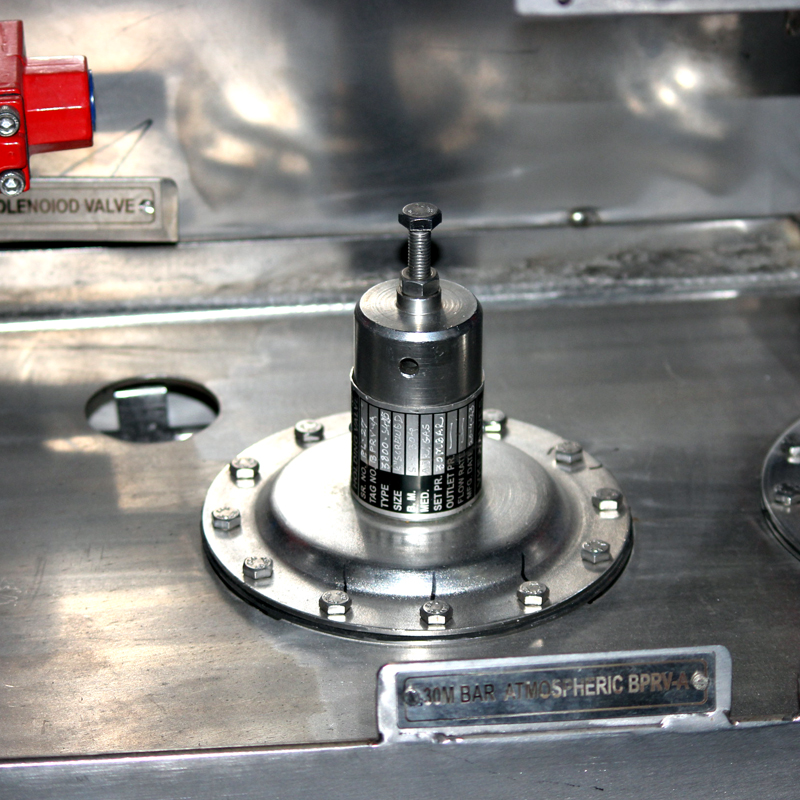

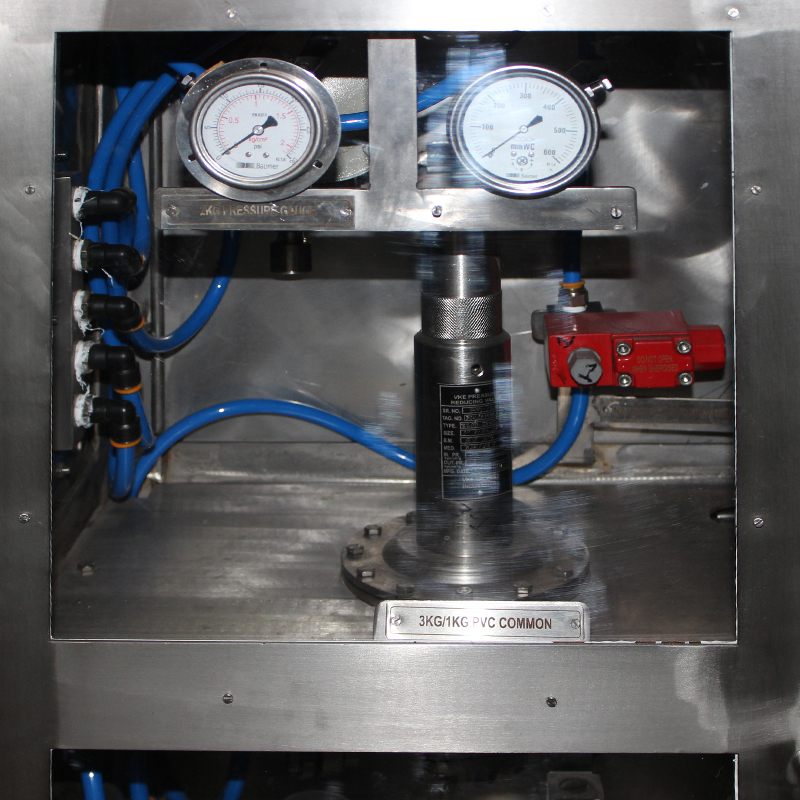

Our inertization design is based on vapor-tight centrifuge construction, combined with a dedicated network of valves, solenoid controls, and pressure switches that function in a coordinated sequence. This ensures that nitrogen purging is consistent, monitored, and failsafe. Purging provisions are provided both for the monitor casing and bearing housing, thereby ensuring complete equipment protection.

Depending on the application, inertization can be operated in semi-automatic mode for basic safety or in fully automated PLC-based mode for advanced process integration. For sensitive operations, an online oxygen analyzer can be incorporated to continuously monitor and restrict oxygen levels within safe operational limits.

Key Advantages

- Explosion & Fire Prevention: Ensures safe operation while centrifuging volatile or flammable solvents.

- Vapor-Tight Construction: Prevents solvent vapor escape and maintains nitrogen atmosphere integrity.

- Full Coverage: Inertization can be applied to both monitor casing and bearing housing for comprehensive safety.

- Automated Control: Available with standalone PLC or integrated with main centrifuge PLC for reliable sequence management.

- Real-Time Monitoring: Optional online oxygen analyzer for continuous oxygen level tracking.

- Regulatory Compliance: Meets stringent pharma and chemical industry safety standards.

- Consistent Product Quality: Protects sensitive materials from oxidation and unwanted reactions.

- Operational Flexibility: Can be configured in semi-automatic or fully automatic mode to suit process needs.

- Enhanced Equipment Life: Reduced corrosion and wear due to controlled atmosphere conditions.

- Process Reliability: Minimizes downtime by ensuring safer and smoother operations under hazardous conditions.